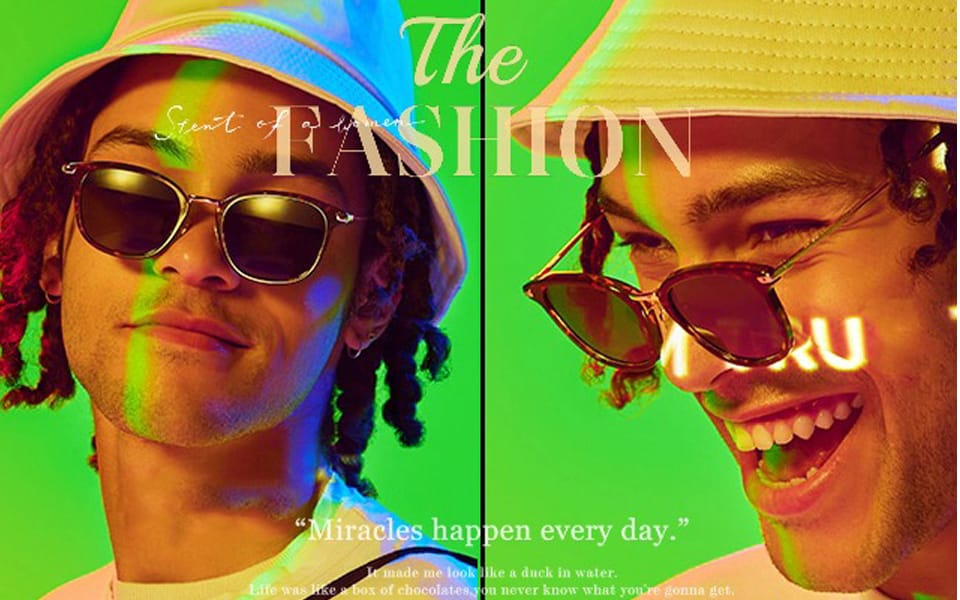

New Design

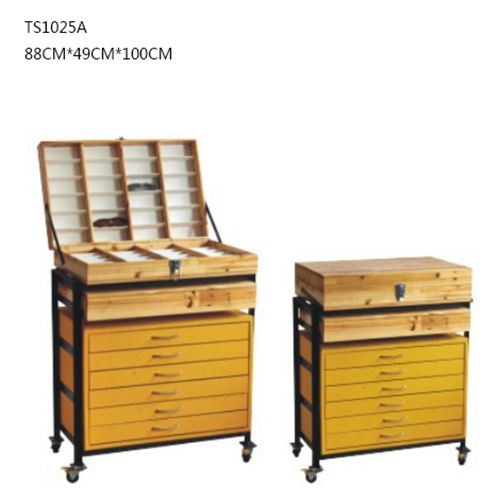

Popular Design In Stock

about us

We are providing competitive prices and high-quality products to open up the global market, and attention to quality craftsmanship, cost performance and customer satisfaction, and aims to continuously provide customers with the best products and win a good reputation.

We serve every customer wholeheartedly with the philosophy of quality first and service supreme. Solving problems in a timely manner is our constant goal. Our eyewear team with full of confidence and sincerity will always be your trustworthy and enthusiastic partner.

see more

see more news

New Stock

newsletter

For inquires about our products or pricelist, please leave to us and we will be in touch within 24hours.

subscribe